Failing the Fit Test: What It Really Says About Your Hearing Protection Program

When a worker fails a hearing protection fit test, it’s tempting to chalk it up to user error or a poor plug choice. But if several workers are failing the test, or if the same worker fails more than once, it’s not just about the plug. It’s a warning sign that your hearing protection program is out of balance.

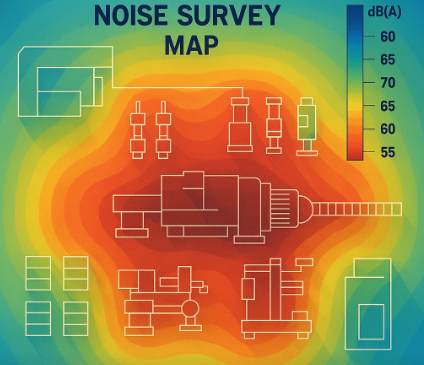

How to Conduct a Noise Risk Assessment and Select Hearing Protection That Actually Works

Noise-induced hearing loss is one of the most widespread occupational illnesses, and it’s irreversible. But it’s also preventable—if you’re using the right strategy. Too many organizations focus only on measuring noise and handing out earplugs. The real value comes from using data to make smart decisions about inclusion in a Hearing Conservation Program (HCP) and matching protection to risk.

Designing Pneumatic Systems with Adequate Safety Performance for Robot Cells

Integrating pneumatic components into robotic work cells presents both opportunities and risks. While pneumatic actuators and valves are essential for tasks like clamping, positioning, or tooling, they must be designed with safety in mind—especially when used in collaborative or hazardous robot operations. To ensure worker protection and regulatory compliance, these systems must achieve a Safety Performance Level (PL) appropriate for their risk—often PL d or PL e.

Choosing the Right Fire Brigade Level for Your Facility

Fire safety is a non-negotiable priority in every manufacturing environment—but not all facilities require the same level of emergency preparedness. The Occupational Safety and Health Administration (OSHA) recognizes multiple levels of workplace fire brigades, each with specific requirements related to training, equipment, documentation, and organizational commitment. Choosing the right level for your site involves balancing risk, regulatory requirements, and operational capabilities.

Protecting Workers from Heat Stress: A Practical Guide for Employers

As temperatures rise each summer, so do the risks associated with heat stress—especially for employees who work outdoors or in hot indoor environments. Heat stress is more than just an uncomfortable condition; it can lead to serious illnesses like heat exhaustion, heat stroke, or even death if not properly managed. For employers and safety professionals, addressing this hazard isn’t just best practice—it’s a legal and moral obligation.

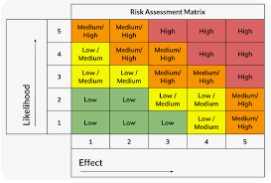

Workplace Safety Risk Assessment Techniques: A Practical Guide

When it comes to preventing injuries and ensuring compliance, nothing beats a solid workplace risk assessment. Whether you're a safety professional fine-tuning your program or a small business just getting started, knowing how to identify and control hazards is foundational. At Vanguard EHS, we believe risk assessments shouldn't just be a compliance checkbox—they should be a core strategy for protecting your people and your business.

Understanding the Safety Standards: ANSI B56.5 vs. ANSI R15.08 for Mobile Robots and AGVs

As workplaces increasingly adopt automation, understanding the applicable safety standards for mobile robots becomes essential. Two commonly referenced standards—ANSI/ITSDF B56.5-2019 and ANSI/RIA R15.08—are often mentioned in the same breath. While they share common goals, they apply to different technologies and use cases. Here’s a breakdown of the key differences and similarities safety professionals need to know

The Critical Role of Leadership Presence in Jobsite Safety Performance

In high-risk industries, safety is not just a policy—it’s a lived experience shaped by leadership. One of the most powerful, yet often underestimated, drivers of safety performance is the physical presence of leaders on the jobsite. Leadership presence isn't about micromanagement or surveillance; it’s about visibility, engagement, and modeling the behaviors that define a strong safety culture.

Digital Lockout/Tagout: Is Paper-Based LOTO Still Defensible in 2025?

Lockout/Tagout (LOTO) procedures are one of the last bastions of analog safety compliance. While nearly every other part of workplace safety has seen digital upgrades—training, incident tracking, inspections—most companies still manage energy control procedures using binders, tags, and checklists.

Rethinking Hearing Conservation: Why OSHA Should Replace Audiograms with Otoacoustic Emissions Testing

Workplace hearing loss is insidious. It doesn’t happen overnight, and by the time it shows up on a standard audiogram, the damage is already done—and permanent

Gamifying Safety Training: Easy Wins for Small Companies

For small companies, safety training often feels like a chore—for both employees and managers. Traditional safety training methods such as slide decks, printed manuals, and lecture-style sessions can be dull and forgettable. Worse, they often result in poor retention and low engagement, especially when workers feel like it’s just another checkbox.

5 Early Warning Signs Your Safety Program Is Failing (And How to Fix Them Before It’s Too Late)

A well-run safety program doesn’t just check boxes—it actively protects people. But even experienced companies can miss the signs that their safety program is starting to slide off course. By the time an injury or OSHA citation brings the problem to light, it's already too late

Reimagining Safety: Using AI to Predict Near Misses Before They Happen

Artificial Intelligence (AI) is transforming safety management in ways once thought unimaginable. While AI-driven hazard recognition and automated compliance tracking are becoming more common, one of the most forward-thinking applications is the use of predictive AI models to identify near-miss events before they occur.

Choosing the Right Earplugs: Understanding NRR and What It Really Means for Your Hearing

Protecting your hearing in noisy work environments is not just a best practice—it’s a necessity. Whether you're exposed to power tools, industrial equipment, or loud recreational settings like concerts or shooting ranges, selecting earplugs with the appropriate Noise Reduction Rating (NRR) can make the difference between long-term hearing health and permanent hearing loss.

How Safety Culture Impacts Hearing Loss Cases in the Workplace

When it comes to workplace hearing loss, most people think of loud equipment, missing hearing protection, or poorly maintained machines. While these are critical risk factors, they’re only symptoms of a deeper issue: safety culture. In workplaces with high rates of occupational hearing loss, there’s often a cultural breakdown that goes beyond decibels and earplugs.

Why Small Businesses Should Prioritize Safety Early: The Case for Adopting a Safety Management System

Starting a business is an exciting time filled with ambition, innovation, and a focus on growth. However, one critical area that is often overlooked by small or upstart companies is workplace safety. Many entrepreneurs assume that formal safety systems are only necessary once a company scales or enters high-risk industries. In reality, adopting a Safety Management System (SMS) or consulting with a safety professional early in the process can save lives, reduce liability, and lay a stronger foundation for sustainable growth.

The 5 Safety Policies Every Small Company Needs Before Hiring Workers

Starting a business is exciting—but nothing derails progress like a preventable injury or a surprise OSHA citation. If you're about to hire your first employee (or just did), now is the time to put a few key safety policies in place. You don’t need a full-blown safety manual—just the core essentials that protect your people and show regulators you’re serious about safety.

Should We Modernize OSHA’s Hearing Loss Age-Correction Tables?

In a February 2024 interpretation letter, OSHA responded to an important question raised by clinicians from Premise Health: Should employers be allowed to use updated, NHANES-derived age-correction tables instead of OSHA’s outdated 1970s-era version in assessing age-related hearing loss for older workers? The answer, as OSHA laid it out, is nuanced—but undeniably significant for occupational health professionals striving for fairness and accuracy in hearing loss evaluations.

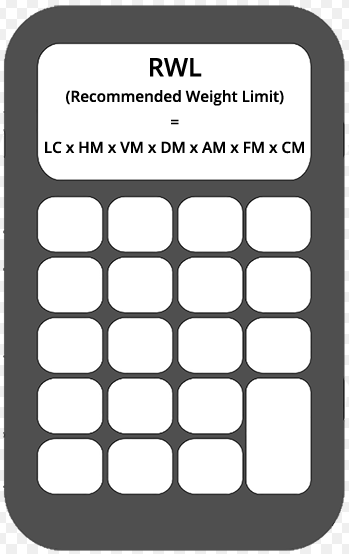

Understanding the NIOSH Lifting Equation: Practical Use for Safer Lifting in the Workplace

The NIOSH Lifting Equation is a scientific tool developed by the National Institute for Occupational Safety and Health (NIOSH) to help evaluate the safety of manual lifting tasks in the workplace. Whether it's a one-time lift or a highly repetitive task, the equation offers a structured way to assess the risk of musculoskeletal injury—especially lower back injuries, which are among the most common workplace injuries in physically demanding jobs.

When Lockout Isn't an Option: OSHA Clarifies “Alternative Methods” in 2024 Interpretation

The U.S. Occupational Safety and Health Administration (OSHA) has issued a significant letter of interpretation (LOI) dated October 21, 2024, clarifying how employers must handle service and maintenance tasks that require machine power — and how far they can rely on so-called “alternative methods” under the Lockout/Tagout (LOTO) standard, 29 CFR §1910.147.