Safely Interacting with Robots in Teach Mode: Best Practices for Human-Robot Collaboration

As industrial robots become increasingly common in manufacturing and warehouse environments, the need for safe human-robot interaction during programming and maintenance tasks grows more critical. One of the highest-risk situations occurs when robots are placed in teach mode, allowing technicians to guide or program the robot manually. This mode often requires proximity to the robot’s moving parts and can bypass normal safeguarding. Without proper controls and procedures, even a slow-moving robot can cause serious injury or death. Fortunately, standards, technology, and training can help mitigate these risks.

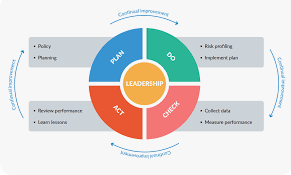

The Importance of Quality Data for Continuous Improvement in Safety Management Systems

In the world of occupational safety, the phrase “you can’t improve what you don’t measure” holds especially true. But not all measurements are created equal. For a Safety Management System (SMS) to mature and evolve, it must be built upon quality data—data that not only reflects the current state of the organization but also points to where risk lives and where interventions can make a measurable difference. Unfortunately, many organizations still rely heavily on lagging indicators, or worse, adopt misleading pseudo-leading indicators that offer the illusion of progress while concealing critical system weaknesses.

How to Handle Baseline Audiograms for Rehired Employees

When it comes to occupational hearing conservation, one often-overlooked challenge is managing audiometric testing for employees who return to the company after a gap in employment. Specifically, if a worker was previously terminated and then rehired two or three years later, how should their baseline audiogram be handled?

Why Regular Fire Pump Inspections Matter: A Guide to Frequency, Compliance, and Best Practices

When it comes to fire protection systems, the fire pump plays a critical role. It ensures that water pressure remains high enough to support sprinkler systems and hose standpipes during a fire emergency. However, like any piece of equipment, fire pumps must be regularly inspected to ensure they function when needed. Skipping or delaying these inspections can result in catastrophic failure at the worst possible time—during an active fire.

Why Hands-On Fire Extinguisher Training Is Essential for Fire Watch Personnel

In many industrial and construction settings, fire watch duties are a critical part of maintaining workplace safety—especially during hot work activities like welding, cutting, or grinding. Fire watch personnel are tasked with monitoring for signs of fire during and after such operations. While many employers provide general fire safety awareness, one crucial component is often overlooked: hands-on training with fire extinguishers.

Reimagining Equipment Safety: How AI is Empowering Human Operators to Prevent Tragedy

In today’s industrial environments, safety technology is advancing faster than ever before—and one of the most exciting developments is the use of AI-powered cameras that don’t just monitor human behavior—they actively help prevent disasters in real time, even on equipment operated by people. These systems are not autonomous driving platforms. They’re designed to work in tandem with human-operated forklifts and other mobile equipment, providing an intelligent layer of protection without replacing the operator.

Substation Safety: How to Lock Out Breakers Before Downstream Work

Locking out a substation breaker before working on downstream electrical equipment isn’t just a box to check—it’s a critical life-safety process. Substations often involve high-voltage systems capable of delivering lethal incident energy. Failing to isolate power sources or skipping verification steps can result in fatal arc flashes or severe equipment damage. This guide outlines a proper lockout/tagout (LOTO) procedure with practical considerations for real-world application.

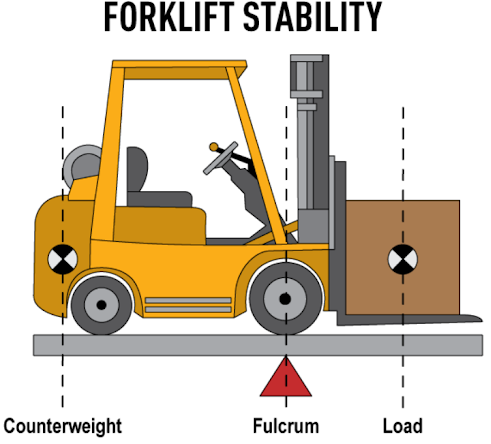

The Importance of Travel Direction on Ramps When Operating a Forklift with a Load

Operating a forklift on a ramp comes with heightened risk. Even a small misstep can result in tipping, load loss, or serious injury. One of the most important—and often misunderstood—rules is the direction a forklift should travel on a ramp when carrying a load.

Forklift Fueling Safety: Batteries, Gas, and Diesel Done Right

Fueling a forklift—whether charging batteries or refueling with gas, diesel, or propane—is a high-risk task that must be done with safety top-of-mind. OSHA enforces strict standards for these operations, and understanding the specific requirements for each fuel type is essential. In addition to regulatory compliance, ergonomic practices and the right PPE are vital for protecting workers from chemical exposure, fire hazards, and musculoskeletal injuries.

Ensuring Stable and Balanced Loads Before Transporting with a Forklift

Transporting loads with a forklift isn’t just about picking them up and driving away—it’s about control, visibility, and stability. OSHA (1910.178(o)(1)) and ANSI standards emphasize the importance of ensuring that all loads are secure, balanced, and safe to move before transport begins. Failure to do so can result in tip-overs, dropped loads, or injury to workers. Let's take a closer look at some common load types and best practices to keep things stable and safe.

When Does OSHA Require a Forklift Pre-Operation Inspection? Scenarios Explained

Forklifts are essential tools in warehouses, construction sites, and manufacturing facilities—but they're also heavy, powerful machines that can pose serious risks when not properly maintained. That’s why OSHA (Occupational Safety and Health Administration) mandates daily pre-operation inspections of powered industrial trucks (including forklifts) before they are put into service. But how often is “daily,” and how does this requirement apply in different real-world situations?

When Welding Turns a Non-Permit Confined Space Into a Permit-Required One

Welding is one of the most common tasks performed in confined spaces—yet it’s also one of the most misunderstood when it comes to permit requirements. A space that normally doesn’t require a permit under OSHA’s Confined Space standard (29 CFR 1910.146) can quickly change classification when hot work like welding enters the picture.

OSHA Standards vs. NIOSH Recommendations: A Detailed Technical Comparison

While both OSHA and NIOSH aim to protect workers, they take very different approaches when it comes to safety thresholds, methodologies, and scope. Below is a deep dive into how their requirements contrast.

Why PPE Fails — and What Your Team Isn’t Telling You

Personal protective equipment (PPE) is often the last line of defense on the jobsite. It’s issued, required, and in many cases, checked off on a safety form. But here’s the uncomfortable truth: PPE doesn’t always get worn the way we think it does—and the real reasons why are rarely written in any incident report.

Rethinking Atmospheric Monitoring in Confined Spaces: A Risk-Based Approach

In confined space operations, it's standard practice to deploy four-gas monitors measuring Oxygen (O₂), Carbon Monoxide (CO), Hydrogen Sulfide (H₂S), and Lower Explosive Limit (LEL). While this approach provides a baseline safety measure, it may not address all potential atmospheric hazards specific to each confined space. Over-reliance on this standard configuration can lead to undetected dangers, as evidenced by various incident reports and studies.

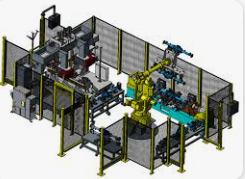

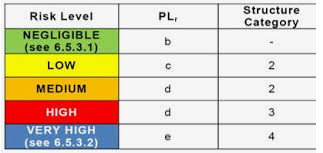

Safety Devices for Robot Cells: Key Components and Their Role in Achieving Performance Levels (PL)

Safety is a critical consideration when designing robot cells, especially as the integration of robotics into industrial processes continues to increase. Ensuring that robot cells are equipped with the right safety devices is essential not only for the protection of human workers but also for compliance with international safety standards. Safety devices such as safety sensors, emergency stop systems, light curtains, and guarding systems work together to ensure that the robot cell operates safely and minimizes the risk of accidents.

How to Calculate Performance Levels for Robot Cells: A Step-by-Step Guide

Calculating Performance Level (PL) for safety systems in robot cells is a critical part of ensuring the safety and reliability of automated systems. Performance Level (PL) determines the risk reduction capability of a safety system, ensuring that the likelihood of a dangerous failure is minimized. Accurate PL calculations are necessary to ensure that robot cells are compliant with safety standards such as ISO 13849-1 and IEC 62061 while also protecting workers from potential hazards.

Box-Checking Safety Is a Lie: It’s Time for a Reality Check

Let’s get one thing straight: safety isn’t about filling out forms. It’s not about signing a clipboard at the start of a shift or checking a box that says “Yep, we’re good.” If that’s the extent of your safety program, you don’t have a safety culture—you have a compliance illusion.

Revolutionizing Workplace Safety: Predictive AI & Wearable Tech

Picture this: You're at work, moving through your daily routine, when suddenly, your smartwatch buzzes with a friendly reminder: "Check your harness before climbing." You didn't even have to think about it. But you’re glad it caught you before you made a potentially dangerous mistake. Or how about this: You're working near a high-powered machine, and your wearable vibrates, alerting you to adjust your posture—just in time to avoid an injury. It’s like having a safety coach that’s always watching your back, right in the moment when you need it most.

Using Magical Tech to Make Workplaces Safer

Imagine the technology that makes a Disney park so seamless—where a wristband unlocks your hotel room, tracks your location, and customizes your experience—being used not for thrills, but to keep people safe at work. That "magic" can be adapted to serious business, especially in high-risk industries like construction, logistics, and manufacturing.