Understanding Performance Level (PL) and Its Importance in Safety Systems

In the context of industrial automation, safety is paramount, particularly in environments that involve robots, automated machines, and other high-risk machinery. As automation continues to advance, the risks associated with these technologies are becoming more complex, and so are the safety standards designed to mitigate them. One of the most critical safety concepts is Performance Level (PL), a crucial element in determining the effectiveness of safety devices and systems

The Importance of Proper Isolation in Confined Space Entry: An OSHA Regulation Breakdown

Confined space work is one of the most hazardous tasks in many industries, with the potential for deadly accidents lurking in every step. One of the most critical steps in ensuring worker safety when entering a permit-required confined space is proper isolation. This requirement is clearly outlined in OSHA's 29 CFR 1910.146(d)(3)(iii), which mandates that employers must isolate the confined space from all hazardous energy, materials, and conditions before any worker enters.

Ladder Safety in Doorways: A Regulatory Gap That Needs to Be Closed

In 2016, a construction worker in New York was working on an extension ladder placed in front of an active doorway. A colleague unknowingly opened the door, knocking the ladder over and sending the worker tumbling 15 feet to the ground. The worker suffered fatal head injuries from the fall. This tragedy could have been prevented with proper ladder placement and regulatory enforcement.

IoT-Enabled Lockout/Tagout: The Future of Workplace Safety

The Internet of Things (IoT) is revolutionizing traditional Lockout/Tagout (LOTO) systems by introducing smart, connected devices that enable real-time monitoring, remote access, and automated compliance tracking

Augmented Reality: A Game Changer for Workplace Safety in Construction and Manufacturing

Workplace safety is a top priority in high-risk industries like construction and manufacturing. Traditional safety training and hazard detection methods have long been the standard, but Augmented Reality (AR) is revolutionizing the way workers prepare for and respond to workplace dangers. By overlaying digital information onto the real world, AR enhances hazard awareness, improves training, and increases overall job site safety.

Encouraging Safety Communication in the Workplace: Processes Aligned with ISO 45001

Effective safety communication is essential for maintaining a strong safety culture and preventing workplace incidents. When employees feel comfortable reporting hazards, sharing concerns, and discussing safety openly, organizations can proactively address risks before they lead to accidents.

Location-Based Microlearning: The Future of Workplace Safety and Training

Imagine walking up to a piece of heavy machinery at your workplace and receiving an instant notification on your phone with a two-minute video explaining its safety features. No searching through manuals, no waiting for a supervisor—just immediate, relevant information when and where you need it.

Understanding Safety Climate and How Employers Can Influence It

In any workplace, safety is a fundamental concern that affects employees’ well-being, productivity, and overall job satisfaction. However, beyond the physical measures like personal protective equipment (PPE) and hazard controls, there is a less tangible but equally important factor—safety climate. Understanding what safety climate is and how employers can shape it can have a profound impact on reducing workplace incidents and fostering a culture of safety.

OSHA vs. NIOSH: Understanding Workplace Safety Regulations and Research

Occupational noise-induced hearing loss remains a significant concern in various industries, prompting the Occupational Safety and Health Administration (OSHA) to implement stringent regulations to safeguard workers. One key regulation, 29 CFR 1910.95(g)(1), mandates an audiometric testing program for employees exposed to high noise levels. However, OSHA isn’t the only agency focused on worker safety. The National Institute for Occupational Safety and Health (NIOSH) also plays a vital role in workplace health, albeit through research rather than enforcement.

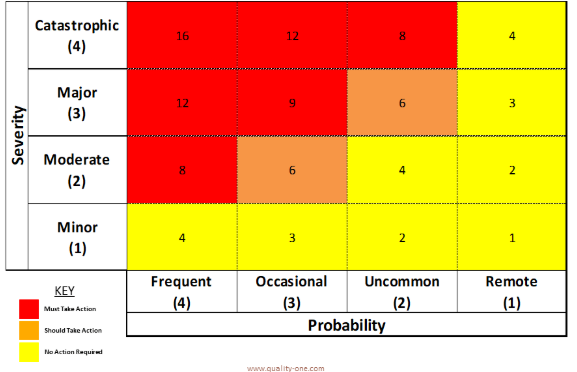

The Limitations of Traditional SFMEA in Risk Assessments

The Safety Failure Modes and Effects Analysis (SFMEA) has long been used in manufacturing and industrial settings to assess risks. This method evaluates risks based on four key factors: severity, controls, frequency, and people. While SFMEA provides a structured approach, it has significant limitations that can result in incomplete or inaccurate risk assessments.

Machine Guarding in 2025: Adapting to New Tech and Regulations

In the fast-evolving world of manufacturing, safety remains a cornerstone of operational success. As we move through 2025, one area demanding attention is machine guarding—an essential practice that protects workers from the hazards of increasingly sophisticated machinery. With automation and robotics transforming production floors, manufacturers must adapt to both new technologies and shifting regulations to keep their teams safe and their businesses compliant

Do I Have to Use a Permit for this Confined Space?

Permit required confined space entries become complicated, time consuming, and expensive very quickly. Often times, setting up to complete a permit required confined space entry can take longer than completing the actual task within the confined space.

What Can be Used as a Lockout Device?

There are many products on the market that are designed for the purpose of being a lockout device in specialized situations, but what if you don’t have them available? What are the requirements?