Choosing the Right Earplug: An In-Depth Guide for Safety Professionals

Introduction: Why Earplug Selection Matters More Than You Think

Noise-induced hearing loss (NIHL) remains one of the most prevalent occupational illnesses in the United States, with over 22 million workers exposed to hazardous noise each year (NIOSH, 2023). Yet, despite robust Hearing Conservation Programs (HCPs), failures in selecting and fitting appropriate hearing protection devices (HPDs) still lead to preventable auditory damage.

Earplugs, as a form of insert-type HPD, are often the first line of defense. But the “one-size-fits-all” approach to earplug selection is dangerously outdated. To be effective, earplugs must match the noise environment, the anatomical characteristics of the user, task-specific risks, and even psychological and behavioral factors that affect use and compliance.

This blog offers a detailed look into the materials, construction, classification, performance, and optimal selection process for earplugs—backed by academic and regulatory research.

Section 1: How Earplugs Work – The Science of Attenuation

Earplugs protect hearing by reducing the sound energy that reaches the tympanic membrane (eardrum). They achieve this primarily through passive attenuation, which means absorbing and reflecting sound waves before they can reach the inner ear. Some models, particularly electronic earplugs, also incorporate active attenuation—an embedded microphone and circuitry that phase-cancels loud impulses.

Key Concepts:

Insertion depth: Deeper insertion increases attenuation, especially at high frequencies (Casali et al., 2009).

Seal quality: A good seal is essential for low-frequency attenuation.

Material properties: Density, elasticity, and surface texture influence both comfort and NRR performance.

Section 2: Types of Earplugs and Their Construction

1. Expandable Foam Earplugs (Roll-down Foam)

Construction: Made of polyvinyl chloride (PVC) or polyurethane (PU) memory foam. Must be compressed (rolled) and inserted into the ear canal, where they expand to seal.

Pros:

High NRR (up to 33 dB)

Inexpensive and disposable

Conforms to most ear canals

Cons:

Requires clean hands for insertion

Inconsistent fit if improperly inserted

Not reusable

Can cause discomfort during long wear

Best Use: High-noise environments like metal fabrication, stamping, heavy equipment operation

2. Pre-Molded Reusable Earplugs

Construction: Made of silicone, elastomer, or rubber; flanged shape with fixed dimensions. No need for rolling.

Pros:

Durable and reusable (up to 2–4 weeks with cleaning)

Easier insertion without rolling

Better suited for dirty environments

Cons:

Requires accurate sizing

May not seal well in nonstandard ear canals

Generally slightly lower NRR (~20–27 dB)

Best Use: Manufacturing, food processing, chemical plants, outdoor work with moderate noise

3. Push-to-Fit (No-Roll) Foam Earplugs

Construction: A foam tip with a semi-rigid stem. Designed to be pushed in rather than rolled.

Pros:

More hygienic than roll-down foam

Easier to train on correct use

Good attenuation (NRR ~28–30 dB)

Cons:

May still cause discomfort with long wear

Limited custom fit compared to roll-down

Best Use: Assembly lines, cleanrooms, dirty-hands environments

4. Banded Earplugs (Canal Caps)

Construction: Foam or silicone plugs mounted on a plastic headband. Designed for intermittent use.

Pros:

Quick removal/insertion

Ideal for short-duration exposure

More acceptable in intermittent-noise environments

Cons:

Lower NRR (typically ~17–22 dB)

Not suitable for continuous high-noise environments

Can interfere with other PPE

Best Use: Maintenance tasks, visitors, jobs with variable noise exposure

5. Custom-Molded Earplugs

Construction: Individually molded to the user’s ear canal using silicone or acrylic. Made via impression or 3D scanning.

Pros:

Excellent comfort and long-term wear

High user compliance

Consistent seal and attenuation

Cons:

Expensive (~$100+ per pair)

Not ideal for growing ears or high turnover

Cleaning and care required

Best Use: Long-shift operations, hearing-critical jobs, long-term employees

6. Electronic (Level-Dependent) Earplugs

Construction: Incorporates microphones, amplifiers, and sometimes Bluetooth. Allows ambient sounds but limits impulse noise.

Pros:

Preserves situational awareness

Ideal for impulse-noise environments (e.g., shooting, stamping)

Some models offer two-way communication

Cons:

Expensive ($150+ per set)

Requires batteries or charging

Not always suitable for continuous high noise

Best Use: Tactical teams, shooting ranges, robotic welding, communication-sensitive roles

Section 3: Understanding Attenuation, De-Rating, and Real-World Performance

Noise Reduction Rating (NRR): Lab vs. Reality

The Noise Reduction Rating (NRR) represents the expected dB reduction provided by a hearing protector when worn correctly in controlled laboratory conditions. However, these ideal circumstances rarely reflect real-world use. Factors such as improper insertion, ear canal variability, and inconsistent compliance can significantly reduce actual protection.

To bridge the gap between laboratory and workplace conditions, agencies like OSHA and NIOSH recommend adjusted calculations—commonly referred to as de-rating.

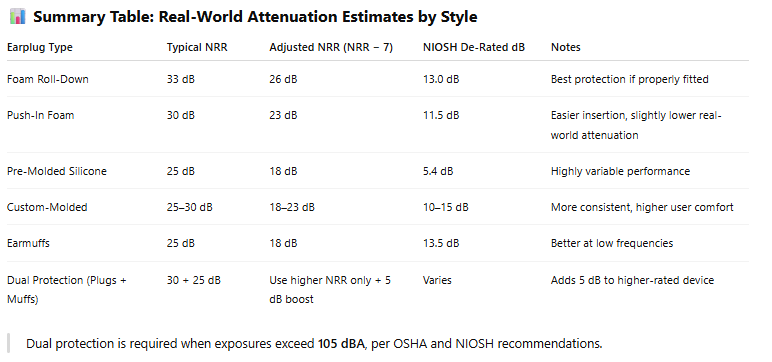

How to Correctly De-Rate NRR

The most widely accepted method for estimating real-world attenuation involves two steps:

🔹 Step 1: Subtract 7 dB

This compensates for the difference between the C-weighted noise scale (used in measurements) and the A-weighted scale (used in lab tests for NRR).

Adjusted NRR = NRR – 7

🔹 Step 2: Apply the De-Rating Factor

Different agencies recommend different de-rating factors depending on the HPD type:

🔸 OSHA Method

For simplicity, OSHA recommends a 50% de-rating across all devices:

Estimated Attenuation = (NRR − 7) × 0.50

🔸 NIOSH Method

NIOSH proposes more refined de-ratings based on the protector type:

✅ Real-World Example

Let’s say an employee is using pre-molded earplugs rated at NRR 25, and the measured noise level is 98 dBC:

Adjusted NRR = 25 − 7 = 18 dB

NIOSH De-Rating = 18 × 0.30 = 5.4 dB

Estimated Exposure = 98 − 5.4 = 92.6 dBA

In this scenario, the pre-molded plug would reduce the worker’s effective exposure to 92.6 dBA — still above the OSHA PEL of 90 dBA and far above the NIOSH REL of 85 dBA, indicating that better protection (e.g., foam plugs or dual protection) is needed.

🎯 Fit Testing: Measuring Actual Attenuation for Individuals

Even with correct de-rating, attenuation is still an estimate. Actual protection varies greatly among individuals, which is why fit testing has become the gold standard in Hearing Conservation Programs.

Fit Testing Methods:

REAT (Real-Ear Attenuation at Threshold): Tests hearing thresholds with and without earplugs to measure attenuation.

MIRE (Microphone-In-Real-Ear): Uses microphones to measure sound pressure in the ear canal during exposure.

Key Findings:

Casali et al. (2009) found that users often achieve only 50–60% of labeled NRR without training.

Custom-molded earplugs show more consistent attenuation across users but not necessarily higher attenuation unless properly seated.

Research by Murphy et al. (2016) found that push-in foam earplugs averaged ~14–18 dB attenuation in real-world settings, compared to their labeled NRRs of 28–33 dB.

Section 4: A Step-by-Step Protocol for Selecting the Right Earplug

Selecting the appropriate earplug involves a systematic approach that considers various factors to ensure optimal protection and user compliance. Here's a detailed protocol:

Step 1: Assess the Noise Environment

Measure Noise Levels: Use sound level meters or dosimeters to determine the Time-Weighted Average (TWA) noise exposure.

Identify Noise Characteristics: Determine if the noise is continuous, intermittent, or impulse-based, as this influences the type of hearing protection needed.

Step 2: Determine the Required Attenuation

Calculate Required Attenuation: Subtract the desired exposure level (e.g., 85 dBA) from the measured TWA to find the necessary attenuation.

Avoid Overprotection: Excessive attenuation can hinder communication and awareness. Aim for a protected exposure level between 75–85 dBA.

Step 3: Evaluate Worker-Specific Factors

Anatomical Considerations: Assess ear canal size and shape to determine the most comfortable and effective earplug type.

Compatibility with Other PPE: Ensure the chosen earplugs do not interfere with other personal protective equipment like helmets or safety glasses.

Communication Needs: For roles requiring situational awareness, consider level-dependent or uniform attenuation earplugs.

Step 4: Select the Appropriate Earplug Type

Based on the assessments:

Foam Earplugs: Suitable for high-noise environments; offer high attenuation but require proper insertion.

Pre-Molded Earplugs: Reusable and easier to insert; ideal for moderate noise levels.

Custom-Molded Earplugs: Provide a personalized fit; beneficial for long-term use and consistent attenuation.

Electronic Earplugs: Best for environments with variable noise levels; allow for communication while protecting against loud sounds.

Step 5: Conduct Fit Testing

Implement Fit Testing: Use methods like Real-Ear Attenuation at Threshold (REAT) or Microphone-In-Real-Ear (MIRE) to measure actual attenuation achieved by the user.

Train Users: Educate employees on proper insertion and use to maximize protection.

Section 5: Fit Testing, Training, and Compliance Monitoring

Importance of Fit Testing

Fit testing ensures that the selected earplug provides the intended protection for each individual. It accounts for variations in ear canal anatomy and insertion techniques.

1. Individualized Training Enhances Attenuation

A study by Murphy et al. (2011) evaluated the effects of different training methods on earplug attenuation. Participants who received one-on-one instruction achieved an average A-weighted attenuation improvement of 5–8 dB compared to those who only received written or video instructions. This enhancement was statistically significant across various earplug types, including foam and pre-molded designs.

2. Systematic Review Highlights Training Efficacy

A 2024 systematic review by Morata et al. analyzed multiple studies involving 756 participants to assess the effectiveness of fit-testing systems and associated training. The review found that simple instructions accompanying fit testing did not significantly improve personal attenuation ratings. However, fit testing combined with extensive, personalized instruction showed promise in enhancing workers' protection against noise immediately after the test and training sessions.

3. Objective and Subjective Measures Confirm Training Benefits

Research conducted by Samelli et al. (2015) compared attenuation values measured by objective (MIRE) and subjective (REAT) methods in groups with and without training. The study demonstrated that the group receiving training on proper hearing protection insertion exhibited higher attenuation values than the untrained group. Specifically, the trained group achieved significantly greater attenuation across frequencies ranging from 500 to 6000 Hz.

Implications for Workplace Safety

These findings underscore the importance of incorporating individualized training and fit testing into hearing conservation programs. By ensuring that employees are properly trained in the selection, fitting, and use of HPDs, organizations can significantly enhance the effectiveness of hearing protection and reduce the risk of noise-induced hearing loss. Implementing comprehensive training programs that include personalized instruction and fit testing not only improves attenuation outcomes but also fosters a culture of safety and compliance within the workplace.

Training and Education

Proper Insertion Techniques: Demonstrate the correct method for inserting earplugs, emphasizing the "roll, pull, and hold" technique for foam plugs.

Maintenance and Hygiene: Instruct on cleaning reusable earplugs and the importance of replacing disposable ones regularly.

Compliance Monitoring

Regular Audits: Conduct periodic checks to ensure consistent use and proper fitting of earplugs.

Feedback Mechanisms: Encourage employees to report discomfort or issues with their hearing protection to facilitate timely adjustments.

Section 6:

Conclusion

Selecting the right earplug is a multifaceted process that requires careful consideration of environmental factors, individual needs, and proper training. By following a structured protocol and emphasizing fit testing and education, organizations can significantly enhance their hearing conservation efforts.

References

NIOSH Science Policy Update: Individual Fit-Testing Recommendation for Hearing Protection Devices. (2025). Retrieved from https://www.cdc.gov/niosh/docs/2025-104/pdfs/2025-104.pdfCDC+1Wikipedia+1

Hearing Protection Fit Testing. (n.d.). Wikipedia. Retrieved from https://en.wikipedia.org/wiki/Hearing_protection_fit-testing

Three Tips for Choosing the Right Hearing Protector. (2018). CDC Blogs. Retrieved from https://blogs.cdc.gov/niosh-science-blog/2018/10/24/hearing-protection/CDC Blogs+1CDC Blogs+1

Selection | Hearing Protection | 3M - US. (n.d.). Retrieved from https://www.3m.com/3M/en_US/hearing-protection-us/support/center-for-hearing-conservation/protect/selection/3M Multimedia+23M+23M+2

Hearing conservation program. (n.d.). Wikipedia. Retrieved from https://en.wikipedia.org/wiki/Hearing_conservation_programWikipedia

Earplug. (n.d.). Wikipedia. Retrieved from https://en.wikipedia.org/wiki/EarplugWikipedia

Hearing Protectors - CCOHS. (n.d.). Retrieved from https://www.ccohs.ca/oshanswers/prevention/ppe/ear_prot.htmlCCOHS

Ear Plug Selection and Fitting Best Practices. (2017). Occupational Health & Safety. Retrieved from https://www3.ohsonline.com/Articles/2017/03/01/Ear-Plug-Selection-and-Fitting-Best-Practices.aspxwww3.ohsonline.com

Hearing protection: OSHA requirements and choosing the right solution for you. (n.d.). Ergodyne. Retrieved from https://www.ergodyne.com/blogs/hearing-protection-osha-requirements-and-choosing-right-solution-youErgodyne

Hearing Protection Fit Testing Technical Bulletin. (n.d.). 3M. Retrieved from https://multimedia.3m.com/mws/media/1578468O/hearing-protection-fit-testing-what-why-how-technical-bulletin.pdf3M Multimedia+13M Multimedia+1